全数字伺服液压机

液压机主机主要由三梁(上横梁、活动横梁、工作台)通过四柱(立柱)及螺母连接紧固在一起构成一整体刚性框架,用以承担液压机的全部载荷,活动横梁与工作台的对应面的平行度及工作台平面对主油缸活塞的垂直可通过调节上横梁下面立柱上的四个调节螺母来实现。具有良好的精度调节功能,为保证机床的精度能够达到使用要求,液压机的立柱与紧固螺母的连接,活动横梁与工作台之间的平行度必须定期按照要求检查恢复。

- 产品描述

-

主要技术参数

Main Technical Parameter

Name 名称

Unit 单位

Data 数值

Remar备注

Pressure压力

Main cylinder Nominal Pressure

主缸公称压力

KN

1200

Ejecting Nominal Pressure

顶出公称压力

KN

/

Max.liquid working pressure

液体最大压力

Mpa

25

Stroke行程

Slide stroke 滑块行程

mm

500

Ejecting stroke 顶出行程

mm

/

OpeningHeigh最大开口高度

The max opening height

最大开口高度

mm

900

The effective size o Worktable

工作台有效面积

Left to right 左右

mm

700

Front to back 前后

mm

620

Speed速度

Descending speed

下降速度

Mm/s

80

Return speed

回程速度

Mm/s

100

Machine total power电机功率

Machine total power电机功率

KW

伺服13.2

Voltage电压

Machine need Voltage 机器需要电压

V

380

Inner diameter of cylinde r缸径

Inner diameter of the main cylinde主缸缸径

mm

/

Weight重量

Machine total weight

机器总重量

Kg

/

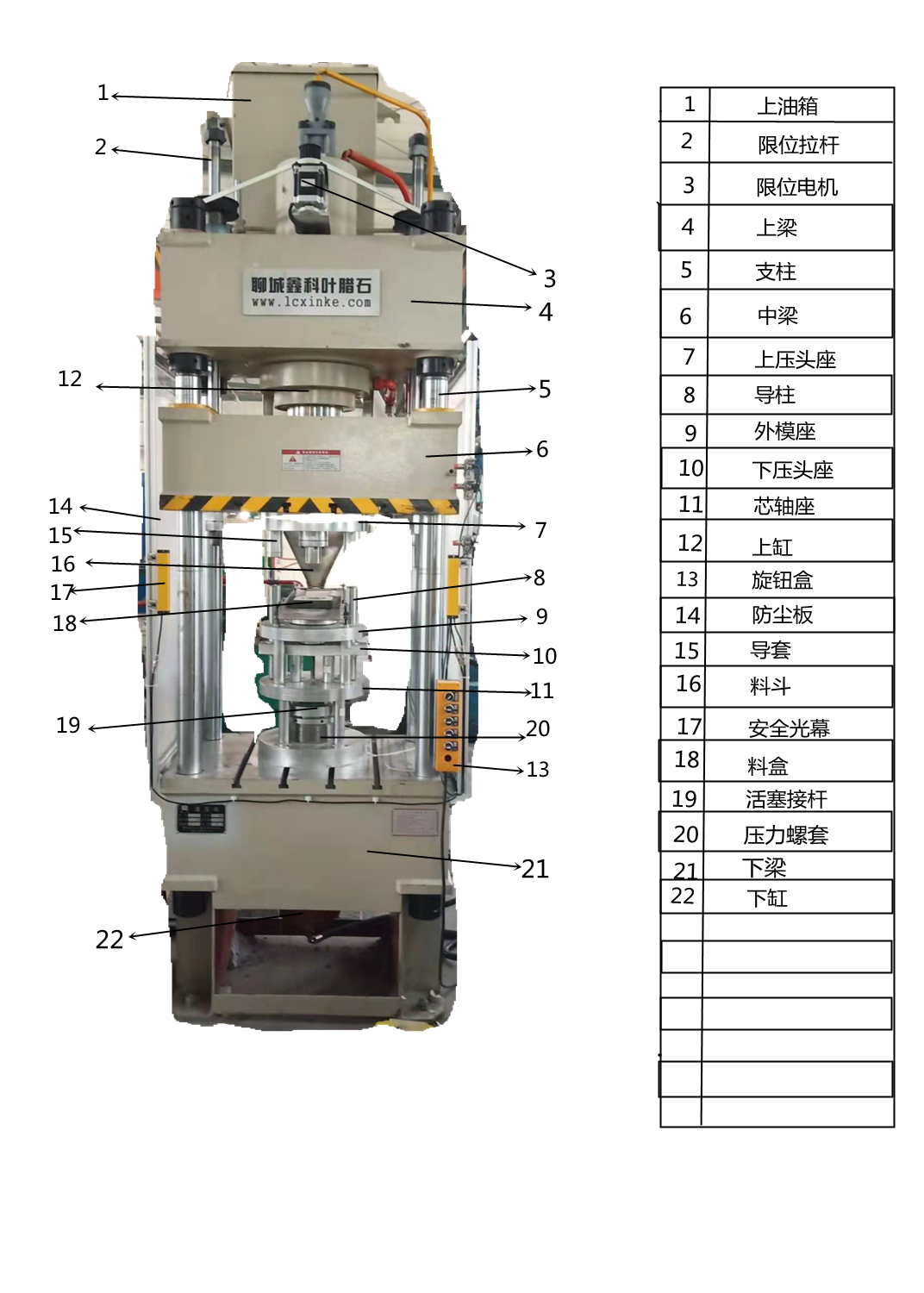

机器的结构、概述

Introduction for Equipment Structure

本机器由主机及控制机构两大部分组成,通过管路及电气装置联系起来构成一整体,现将各部分结构和作用分述如下:

The hydraulic press machine consists machine frame and control system two parts.The two parts are connected to a whole by connected line and electric installant.Each part of the machine is described as following:

1)主机 Machine frame

液压机主机主要由三梁(上横梁、活动横梁、工作台)通过四柱(立柱)及螺母连接紧固在一起构成一整体刚性框架,用以承担液压机的全部载荷,活动横梁与工作台的对应面的平行度及工作台平面对主油缸活塞的垂直可通过调节上横梁下面立柱上的四个调节螺母来实现。具有良好的精度调节功能,为保证机床的精度能够达到使用要求,液压机的立柱与紧固螺母的连接,活动横梁与工作台之间的平行度必须定期按照要求检查恢复。

The machine frame is made of the upper beam,moving beam and worktable.The upper beam,moving beam and worktable are connected to a overall rigidity work-frame by four column and nuts.The overall rigidity work-frame will bear all the load of the hydraulic press.The depth of parallelism between moving beam and worktable,and the verticality between the plunger of main oil cylinder and the worktable can be adjusted by four regulating nuts on the column under the upper beam.The accuracy of the depth can be adjusted as the need of the users.The connecting between four columns and clamp nuts and the depth of parallelism between moving beam and worktable must be checked and recovered as needed regularly.

2)主缸 The main cylinder

主缸是本机床的动力转换装置,液压油能通过主缸转化为做功用的压力,它是本机床的心脏部件,缸体与活塞杆之间依靠橡胶密封件可靠密封,主缸上的所有零件均属精密零件,要求精心保护、保养、橡胶密封经过一段时间后会因为老化而损坏,应及时由专业人员更换,确保其稳定的工作效率。

The main cylinder is the power shifting device of the machine.The hydraulic oil can generate the needed pressure via the convert of the main cylinder.It is the heart part' of the machine.The gap between main cylinder and piston rod is reliably sealed by rubber sealing articles.All parts on the main cylinder are accurate parts.They need carefully protection maintenance.The rubber sealing articles can be worn out after a period of time,so please let professional staff check and exchange the sealing articles.making sure the stable working efficiency.

3)顶出缸 Ejection cylinder

安装于工作台内一只工作缸,动作原理同主缸,与主缸配合可以实现更多的动作,满足更复杂的工艺需要,随具体工艺需要此装置在订购时取舍。

The ejection cylinder is installed in one work cylinder of the worktable.it has the same work theory with the main cylinder.It works with the main cylinder to realize more actions.meeting the need of more complicated craft.It is the need of craft that determines whether the machine needs ejection cylinder or not.

4)操纵台 Operating floor

操纵台可以在一定范围内随意移动,可设双手操作结构,使机床实现安全操作。

工作时,操作员必须双手按下分设操作系统两端下降的按钮机床才能动作。

The operating floor can be moved optionally within the limits.It can be designed the two hands operation,making the operation safer.when working,the operator must press the down button ,the machine can act.

5)行程限位装置 Stroke limit installation.

行程限位装置位于机身右侧面,为机床位置检测系统,为实现机床的自动、半自动工作而设计的装置,检测机床的动作位置或状态,发出警报或信号,启动或停止机床的动作。

The stroke limit installation is installed on the right side of the machine frame.It is the piston detector system of the machine.It is designed to realize the automatic operation and semi-autmatic operation.checking the action piston and condition of the machine.issuing warning and signal to warn the operation to start and stop the action.

6)液压泵站(动力系统)Hydraulic pump(dynamical system).

液压泵站是由油箱、电动机、阀总成、油泵等组成,上设有空气过滤器,液位计等装置,其工作原理为电机带动油泵工作提供动力源,通过液压阀等驱动装置(油缸)进行方向压力的调节和控制,实现各种规定动作。

The hydraulic pump is made of oil-box,motor,valve ,pump and so on.it has the installation of air filter,liquid indicator and so on.its working principle is that the motor drives pump to provide the power source, through the hydraulic valve drive device for pressure regulation and control of action to achieve the various specific actions.

关键词:

留言咨询